Prefabricated steel buildings are those which are manufactured off-site at parties and then transported and assembled at the final location. The main features of these buildings are that they can be set up very quickly without the hassles of construction site construction. Not only are they low in costs, but also provide greater flexibility in the design. They may even be moved from one place to another, if necessary. They are made of various materials such as aluminium, steel, wood, fiberglass or concrete, so as to ensure the security and sustainability. Whether one small room or a huge sprawling factory, prefabricated buildings can be easily chosen.

Prefabricated buildings include both mobile trailers and modular structures. They can be pooled in a building already built. In exceptional cases, they may even be assembled on a concrete base not. No wonder Prefabricated Buildings were considered very useful by the disaster struck areas where immediate temporary structures to be erected for shelter and supplies. Even in areas prone to earthquakes prefer to have these prefabricated buildings because they are lighter in weight and less cost. And if for some reason a building is required only for a very short period, then it is viable to go in a prefabricated structure.

Lot of steel or metal building structures, such as schools, apartments, offices, retail stores, fast food joints, guard booths, the doors of houses, toll booths, equipment enclosures, smoking shelters, the arena sports, observation towers, the ticket booths, parking booths, storage buildings, dairy facilities equestrian buildings, recreational areas and military establishments are frequently performed using prefabricated technology.

To make the houses at low cost, prefabricated materials, such as straw bales, Ferro cement products calcium silicate, composite materials and other wood-based cheap are currently used. Calcium silicate bricks are strong and durable. Ferro-cement consists of a matrix of cement reinforced by a mesh closely spaced iron bars or wires. In this type of construction, the techniques used are simple and fast.

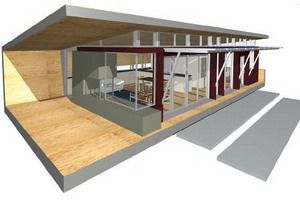

Prefabricated buildings can be assembled quickly, sometimes within a few hours. They come from different facilities, including electrical wiring, doors, windows, shelves of bulletproof windows and climate control systems. Most manufacturers offer many years of coverage for structural damage, leaks, and wind loads. They can even be made in multiple stories. You can select the wall panels, frames and columns, floors, ceilings, doors and windows. Beyond advice, they are available in several colors.

By using prefabricated materials, we can improve our home; we can make it sustainable, water and fire-resistant and cheap prefabricated buildings. Most of the prefabricated building materials likes steel or metal are environmentally friendly and affordable.

But there are some drawbacks to the prefabricated buildings.

They are likely to depreciate faster than the construction site of the houses because they are not yet very popular. Also, the appearance of prefabricated buildings did not offer the diversity of a building built on the site using traditional methods.

They are likely to depreciate faster than the construction site of the houses because they are not yet very popular. Also, the appearance of prefabricated buildings did not offer the diversity of a building built on the site using traditional methods.

Most prefabricated buildings are sold by dealers, but some manufacturers sell directly between them. From where you buy, check the manufacturer’s reputation get into contact with references and ask them about their experiences. It is best to take quotes from several suppliers before you complete your order.

Hi

BalasHapusIt has been some time since I visited website with such high quality information about regarding . Thank you so much for providing such helpful information dave burke

I think it looks amazing. I'm not sure I would have had the patience that you had though! Santa Barbara Green Construction

BalasHapus